Oven-Dryer-Borma-Hot Chamber-Four

A Cashew Nut Dryer is another important equipment after shelling section in a cashew processing unit. This is needed for conditioning of kernel before peeling operation. Well dried cashew kernel with low moisture content releases testa from the surface of kernel thus eases in peeling off testa without breaking kernel, while doing so.

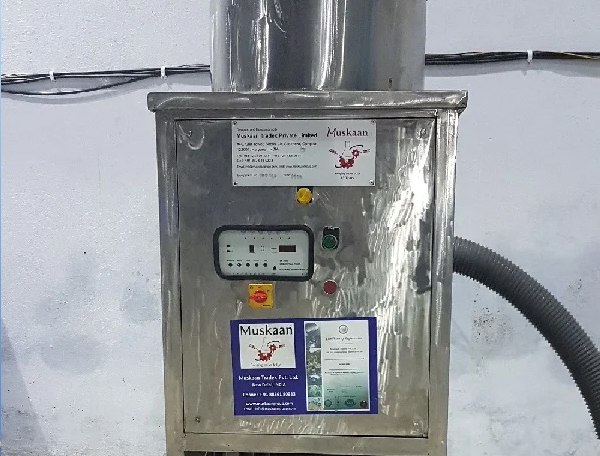

Cashew Nut Drying Machine / Hot chamber / Borma/ Oven / Cashew Dryer

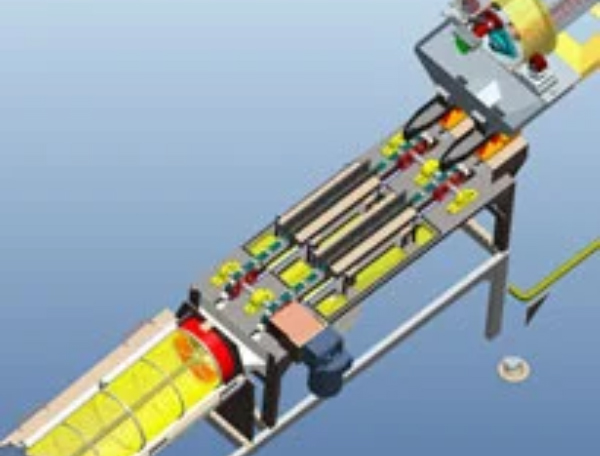

Muskaan specialises in drying technology, we have vast range of dryers in offering including fully Automatic dryers, highly efficient design, for uniform drying of cashew kernel, drying mango, Ginger, and Hibiscus comes with many futures of automation. We manufacture cashew dryers in different capacities and using different heat sources, from Steam, to electricity to direct heat.

In summary, Muskaan Dryers are a flexible drying system with multiple components that can be customized to suit cashew kernel drying needs. Cashew Borma adaptability and precision make it a valuable tool for ensuring efficient and controlled drying processes.

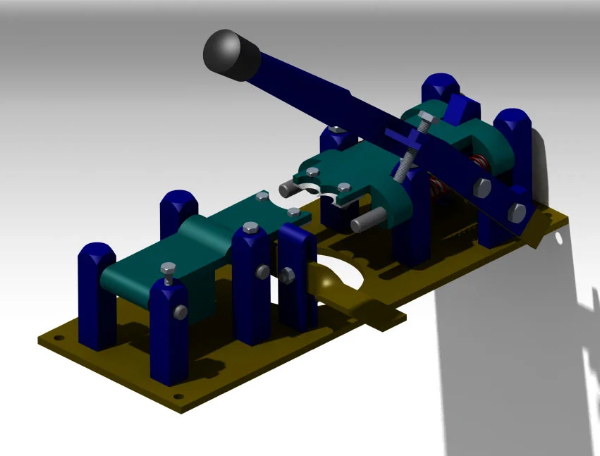

So as technology providers our driers are good with following features:

- Uniform drying across the chamber with uniform flow of hot air inside.

- Hygienic / food grade design

- Use of steam and electricity as a drying medium as per customers choices

- Higher capacity

- Fully automatic in operations

- Lesser time for drying

- Lower final moisture content

- Easy to operate features

- Extremely low cost of maintenance

- Highly reliable

- Well insulated for lowest energy consumption

- Strong Ruggest built construction

- Modular design for increasing capacity at any future time

Client Include:

- 2,000 Ton Per Year

- 5,000 Ton Per Year

- 10,000 Ton Per Year

Our Achievement

75+ Running Cashew Processing plant in African Countries. Most suitable automatic and manual processing technology according to user requirement. Global team with Subsidiaries is Ivories Coast